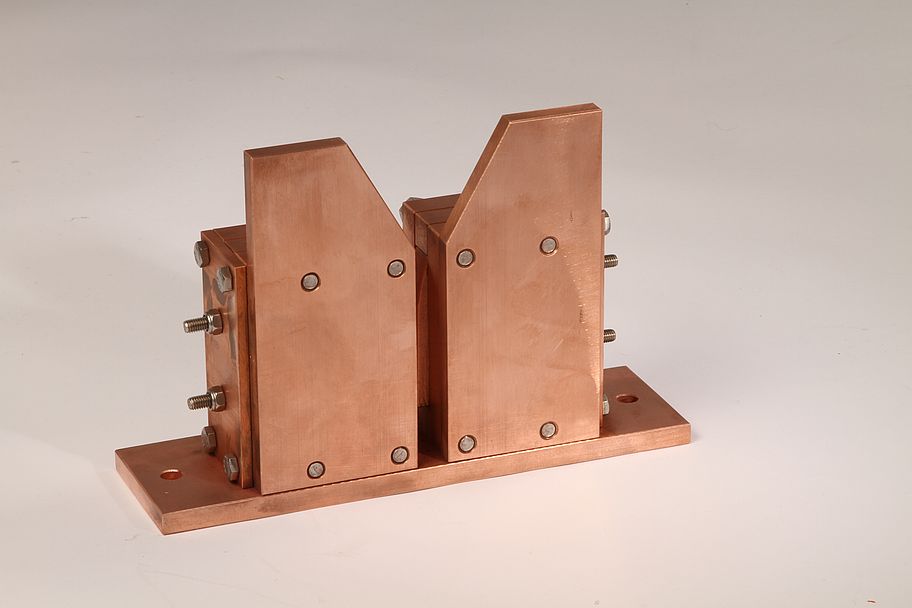

Plate-contacts

Key Facts

-

Current

1.500 A - 8.000 A

-

Sensor

Optional thermal monitoring with PT-100 / PTC80

-

Special features

Especially suitable for alkaline zinc plants

Easy to assemble

Optimum current transfer

Fast cycle times, larger throughput quantities and ever higher current densities require high-performance contacts in electroplating and anodizing systems!

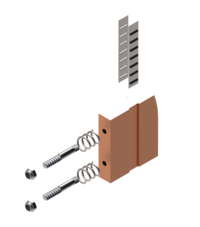

The ampac -P- system creates the prerequisites. Individually mounted contact blades provide optimum current transfer to the busbars.

New standards

The ampac-P system sets new standards.

The mechanically almost indestructible design withstands even the toughest loads from heavy and heaviest merchandise supports.

Protection through plastic jacket

The ampac -P- system is available on request completely protected in an acid and alkali-resistant plastic jacket! This means protection all around.

Advantages of ampac-P-System

The ampac-P-System fits everywhere and it is ready for connection.

Additional substructures and connection lugs are not required in most cases.

The ampac-P system is particularly well suited for alkaline zinc plants.

ampac-P contacts are supplied ready mounted on an E-copper base plate and are adjusted to the respective busbar.

The contacts can either be screwed directly onto busbars or connected to the feeding busbars via corresponding connection brackets.

Our staff will be pleased to advise and support you.

On request, installation can be carried out by our specialist fitters.

We offer complete solutions for every application.

Contact-Standard

| Current Ampere | Busbar thickness | Part-No. Contact Standard | order request |

|---|---|---|---|

| 1500 | 10 | 9015001 | Request |

| 1500 | 15 | 9015001 | Request |

| 1500 | 20 | 9015001 | Request |

| 2000 | 10 | 9020001 | Request |

| 2000 | 15 | 9020001 | Request |

| 2000 | 20 | 9020001 | Request |

| 2500 | 10 | 9025001 | Request |

| 2500 | 15 | 9025001 | Request |

| 2500 | 20 | 9025001 | Request |

| 3500 | 10 | 9030001 | Request |

| 3500 | 15 | 9030001 | Request |

| 3500 | 20 | 9030001 | Request |

| 4000 | 10 | 9040001 | Request |

| 4000 | 15 | 9040001 | Request |

| 4000 | 20 | 9040001 | Request |

| 6000 | 15 | 9060001 | Request |

| 6000 | 20 | 9060001 | Request |

| 8000 | 20 | 9080001 | Request |

Contact Insulated

| Current Ampere | Busbar thickness | Part-No. Contact Insulated | order request |

|---|---|---|---|

| 1500 | 10 | 9015002 | Request |

| 1500 | 15 | 9015002 | Request |

| 1500 | 20 | 9015002 | Request |

| 2000 | 10 | 9020002 | Request |

| 2000 | 15 | 9020002 | Request |

| 2000 | 20 | 9020002 | Request |

| 2500 | 10 | 9025002 | Request |

| 2500 | 15 | 9025002 | Request |

| 2500 | 20 | 9025002 | Request |

| 3500 | 10 | 9030002 | Request |

| 3500 | 15 | 9030002 | Request |

| 3500 | 20 | 9030002 | Request |

| 4000 | 10 | 9040002 | Request |

| 4000 | 15 | 9040002 | Request |

| 4000 | 20 | 9040002 | Request |

| 6000 | 15 | 9060002 | Request |

| 6000 | 20 | 9060002 | Request |

| 8000 | 20 | 9080002 | Request |